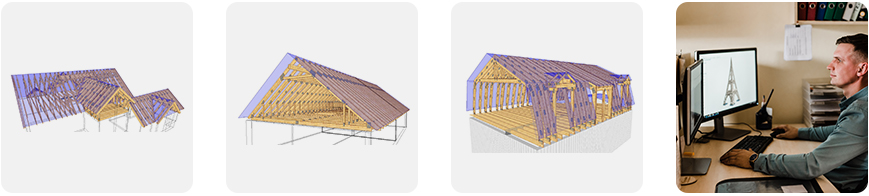

Wooden trusses are industrially manufactured wooden roof constructions, the elements of which are interconnected by special metal connector plates with integral teeth. A special high-force press, that evenly joins the truss elements to one rigid unit, is used for the process. This maximizes the properties of wood and metal and results in a reliable, optimal and long-lasting product.

From us you can receive all roof truss services from consulting to design, production and on-site delivery. We produce trusses for buildings of all types and complexities – from garages to large extensions. We design and manufacture roof constructions not only for our kit house projects, but also as a separate order. To estimate the cost of truss production for your house we will require architectural drawings from you – floor plans, sections, facades and, if you have, roof plans.